Monitoring multiple gases often means double the hardware, power, and complexity, but it doesn’t have to.

Dual-gas infrared (NDIR) sensors provide a compact and efficient solution by combining two independent gas measurements in a single module.

From biogas plants to HVAC systems, these advanced sensors are transforming how OEMs design gas detection systems. In this post, we’ll examine how dual-gas sensors operate, their key advantages, and how to select the right one for your specific application.

How Dual-Gas Infrared Sensors Work

Infrared (IR) gas sensors operate on a simple but powerful principle: each gas absorbs infrared light at specific wavelengths. By measuring the amount of light absorbed at those wavelengths, the sensor accurately and reliably determines the gas concentration.

Dual-gas infrared sensors take this one step further. Instead of using two separate sensors to monitor two gases, they combine dual optical channels or filters into a single module. Each channel detects its own gas type independently, for example, methane (CH₄) and carbon dioxide (CO₂), while sharing the same light source, detector, and signal-processing electronics.

The result? Two precise measurements from one compact, efficient sensor.

This approach not only saves space and power but also reduces overall system cost and complexity, a significant advantage for OEMs designing portable, embedded, or multi-point detection systems.

Key Benefits of Dual-Gas Infrared Sensors

1. Space and Weight Savings

With two sensing channels built into one unit, engineers can achieve the same functionality as two separate sensors while saving valuable space, a crucial factor in portable or space-constrained designs.

2. Lower Power Consumption

By sharing a single IR source and detector, dual-gas sensors draw significantly less power than two individual devices. This makes them ideal for battery-powered analyzers, portable safety instruments, and other energy-sensitive systems.

3. Cost Efficiency

Combining two measurements into one sensor reduces the number of components and wiring required, thereby lowering both production and long-term maintenance costs.

4. Simplified Integration

With a single housing and unified output interface, OEMs can integrate a dual-gas module more quickly and with fewer connection points, thereby accelerating time-to-market.

5. Improved Reliability

Dual-gas sensors are factory-calibrated to ensure both channels remain stable and accurate under identical operating conditions. This consistency enhances performance and reduces the frequency of recalibration in the field.

Typical Applications for Dual-Gas Sensors

The versatility of dual-gas infrared sensors allows them to support a wide range of industries and applications:

In biogas production, simultaneous measurement of methane and carbon dioxide is critical for process efficiency and safety. A dual-gas IR sensor simplifies system design while providing reliable, real-time data on gas composition.

Oil & Gas and Industrial Safety

For confined spaces and process areas, monitoring hydrocarbons such as methane alongside CO₂ provides an early warning of leaks or incomplete combustion.

Refrigeration and Environmental Systems

Dual-gas sensors can detect refrigerant gases in combination with CO₂, supporting leak prevention, energy efficiency, and compliance with environmental regulations.

Process and Emissions Control

Industrial plants utilize dual-gas sensing to monitor gas mixtures in combustion, flue gas, and chemical production processes, thereby helping to maintain product quality and reduce emissions.

In each case, the dual-gas design simplifies installation and enhances reliability, particularly in systems where maintenance access is limited or safety is a critical concern.

How to Choose the Right Dual-Gas Infrared Sensor

Selecting the best sensor for your application requires careful consideration of technical and environmental factors. Here are the key points to evaluate:

1. Gas Combination

Not all gas pairs can be measured effectively with a single sensor. Select compatible combinations such as CH₄/CO₂ or CH4/HCO₂.

High-quality dual-gas sensors use narrow-band optical filters to prevent cross-interference and ensure accurate readings.

2. Measurement Range and Accuracy

Match your sensor’s measurement range to expected gas concentrations. For example, biogas applications typically require a broader range of CO₂ concentrations, while HVAC systems may need higher sensitivity at lower concentrations.

3. Environmental Conditions

Consider operating temperature, humidity, and vibration levels. For harsh or hazardous environments, choose sensors with ATEX or IECEx certifications to ensure safe and compliant operation.

4. Power and Communication Requirements

Low-power models are best suited for portable equipment, while standard versions are ideal for fixed installations. Confirm compatibility with your system’s communication interface.

5. Customisation Options

Each application is unique. That’s why we work closely with our customers to understand their needs and ensure we provide the most suitable sensor for their requirements, and then help them get the most out of it. Dynament offers OEM-focused customisation, from wavelength selection and mechanical design to calibration ranges and output configuration. This ensures seamless integration into your system design.

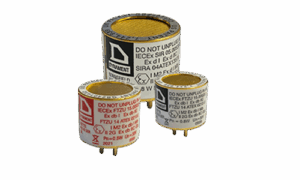

Why Choose Dynament Dual-Gas Sensors

For over 25 years, Dynament has been at the forefront of infrared gas sensor innovation, developing reliable, high-performance solutions for OEMs worldwide.

Our dual-gas NDIR sensors are designed and manufactured in the UK using advanced optical design and precision calibration processes. They are available across multiple product ranges, including Standar d, Low Power, and Safe Area models, ensuring suitability for both portable and fixed installations.

d, Low Power, and Safe Area models, ensuring suitability for both portable and fixed installations.

Each Dynament sensor is engineered for:

- Exceptional accuracy and repeatability

- Low power consumption and compact design

- Compliance with ATEX, IECEx, and UL certifications

- Proven long-term stability and reliability

Dynament’s commitment to R&D, application support, and quality assurance ensures that every sensor delivers consistent performance, even in the most demanding environments.

Conclusion

Dual-gas infrared sensors represent a more innovative and efficient approach to gas detection, combining a compact design, low power consumption, and high accuracy in a single, powerful module.

For OEMs, this means faster development, lower costs, and greater design flexibility, without compromising performance or safety.

Seeking a dual-gas solution tailored to your specific application?

Explore Dynament’s full range of dual-gas infrared sensors or contact our technical team to discuss your gas combination requirements.