Greenhouse Gas Monitoring Sensors

NDIR Infrared Gas Sensors for OEM Greenhouse & Controlled-Environment Systems

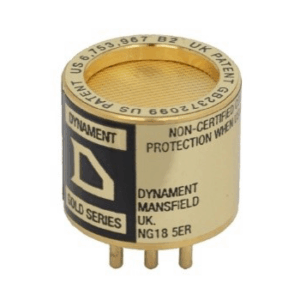

Modern greenhouses and controlled-environment agriculture systems rely on accurate gas monitoring to optimise plant growth, increase crop yield, and maintain safe operating conditions. Dynament manufactures high-performance NDIR infrared gas sensors designed for integration into OEM greenhouse monitoring, CO₂ enrichment, and environmental control systems.

Our sensors provide reliable, long-term measurement of carbon dioxide (CO₂), methane (CH₄), and other gases commonly monitored in greenhouse environments, supporting both plant growth optimization and facility safety.

Explore the Dynament NDIR gas sensor range

Developed for OEM Greenhouse & Automation System Manufacturers

Dynament sensors are selected by:

- OEM greenhouse climate and environmental controller manufacturers

- Automation and monitoring system integrators

- Smart agriculture / precision growing platforms

- Fixed safety and plant-room gas detection systems

Typical integration environments include:

- CO₂ enrichment monitoring and control

- Climate and ventilation management systems

- Distributed environmental monitoring networks

- Boiler, biomass, and energy plant safety monitoring

Our compact OEM sensor modules are designed for fast integration, stable continuous operation, and a long service life.

Learn more about OEM integration capabilities

Key Gases Measured in Greenhouse Applications

Carbon Dioxide (CO₂) — Plant Growth & Yield Optimisation

CO₂ enrichment improves photosynthesis and crop productivity. Accurate CO₂ monitoring allows:

- closed-loop enrichment control

- prevention of unsafe over-concentration

- optimisation of ventilation / heat balance

- improved system energy efficiency

Dynament NDIR CO₂ sensors deliver:

- high measurement stability

- rapid start-up

- minimal calibration requirements

They are widely used in automated greenhouse and plant growth control systems.

Methane (CH₄) — Energy Plant & Boiler Room Safety

Methane may be present in:

- biomass heating systems

- natural gas boiler rooms

- composting or anaerobic decomposition areas

Dynament CH₄ sensors support:

- early leak detection

- continuous fixed-point monitoring

- facility safety compliance

Our methane sensors are trusted in safety-critical and industrial environments, where reliable detection performance is essential.

Technical Advantages of Dynament NDIR Sensors

Dynament greenhouse application sensors provide:

- ✔ NDIR infrared sensing technology

- ✔ High accuracy and repeatability

- ✔ Excellent long-term operational stability

- ✔ Low drift, low-maintenance design

- ✔ Low-power consumption for distributed networks

- ✔ Compact, lightweight OEM module format

Multiple configuration and measurement range options are available to support different greenhouse operating conditions and control strategies.

Download sensor datasheets

Example Specification Summary (typical options available)

| Measurement principle | Non-Dispersive Infrared (NDIR) |

| Target gases | CO₂, CH₄ (other gases available) |

| Measurement range options | Parts per million (ppm) up to %-volume (gas dependent) |

| Repeatability | High stability / low drift |

| Output formats | Digital / analogue, or both (model dependent) |

| Warm-up time | Fast start-up |

| Power consumption | Suitable for low-power distributed systems |

For detailed values, refer to the relevant product datasheet.

Contact our team for application-specific guidance

System Integration & Platform Compatibility

Dynament sensors are designed for seamless integration into:

- embedded controller boards

- PLC-based automation systems

- IoT and remote greenhouse monitoring platforms

Integration features include:

- digital and analogue output options

- standby / low-power mode support

- compatibility with automated control networks

Our team can support:

- sensor selection and range configuration

- integration best-practice recommendations

- calibration and performance optimisation

to help achieve the required accuracy and reliability in your application.

Benefits for Greenhouse Operators & System Designers

Using Dynament NDIR infrared sensors enables:

- ✔ improved crop growth through precise CO₂ regulation

- ✔ stable long-term environmental monitoring

- ✔ reduced maintenance and calibration effort

- ✔ safer operation of heating and plant equipment

- ✔ reliable measurement for automated control systems

Dynament sensors are well-suited for both commercial production greenhouses and research-driven growing environments, where measurement performance and uptime are crucial.

Frequently Asked Questions

Why are NDIR infrared sensors used for greenhouse CO₂ monitoring?

NDIR technology offers selective, stable and long-life CO₂ measurement, making it ideal for continuous monitoring and automated control environments.

Can Dynament sensors be integrated into OEM greenhouse control systems?

Yes — Dynament sensors are supplied as compact OEM modules designed for integration into embedded electronics and environmental control platforms.

Are the sensors suitable for continuous, fixed-point monitoring?

Yes — Dynament sensors are widely used in fixed gas detection and continuous environmental monitoring applications requiring long-term stability.

Contact Our Technical Team

If you are developing a greenhouse monitoring, CO₂ enrichment or environmental control system, our application specialists can help you select the most suitable sensor for your design.